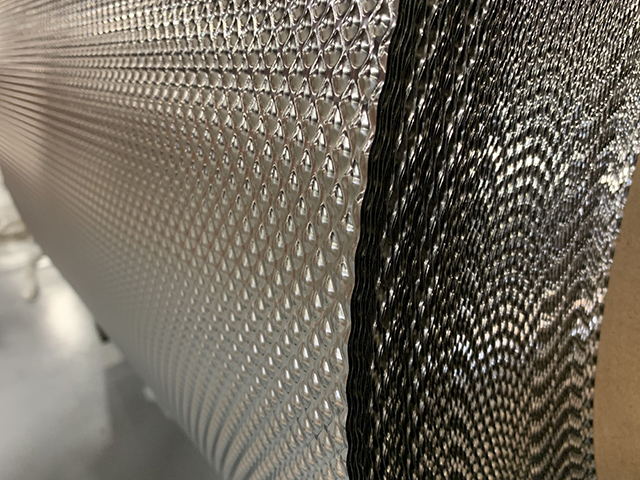

Stainless Steel Tool Wrap is typically .002” thick type 309 or Type 321 Stainless Steel foil used to wrap metal tools, dies, and other parts during high-temperature heat-treating to achieve a hardened temper. The part to be heat-treated is placed in an envelope formed by folding a foil sheet in half and sealing the open ends to lock out the surrounding air. If the seal is not airtight, excess oxygen can be drawn in and cause a loss of carbon on the surface of the part, referred to as “decarburization”, which prevents the outer surface from obtaining the desired hardness and could potentially causing scaling on the part.

To help ensure a tight seal, the foil sheet should be double the size of the part plus an extra three inches on all sides to fold over and crease the edges and then to flatten with a steam roller. It is important to always wear protective gloves when handling the foil to avoid cuts from the sharp edges and burns from the foil after heating. This material is extremely thin and can be dangerous when handled. When choosing between the Type 309 or Type 321 alloys one must consider the operating temperature needed for heat-treating the part.

The standard Stainless Steel Tool Wrap is Type 321, which will work in temperatures up to 2000 degrees Fahrenheit. Tool Wrap in the alloy of 309, will work in temperatures up to 2240 degrees Fahrenheit, for applications needing a little extra heat.

Comet Metals rolls are generally in widths of 24” wide, with 36” and 39.5” widths available when required. Standard roll lengths are approximately 100 feet, but can also be longer or shorter as needed. If you have a special application, we can provide this material in any desired width to maximum a customer’s productivity. Have questions? Feel free to give us a call to discuss how Comet Metals can be your values supplier for all your tool wrap needs.