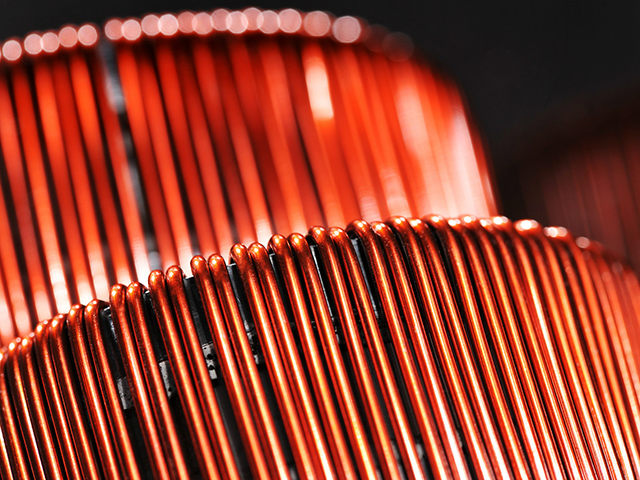

Transformer coil sizes play an important role in the transformer industry. It has long stood as one of the most competitive markets dealing with commodity metals; namely, Copper and Aluminum. If you are purchasing commodities in the transformer industry, you are consistently looking for ways to reduce costs, or at the very least, keep the price consistent to keep up with the competition and market conditions.

For many, the solution to this problem is to use their buying power to purchase in larger quantities to help reduce the price. However, some original manufacturers, as well as rebuilders of transformers, are unable to consolidate their buying due to market demands, but there is another option beyond purchasing more material.

One of the easiest ways to minimize your costs is to provide the weight or length of the materials needed per individual unit that you are trying to build. This step assists a supplier in providing their customer the right amount of material for the job with the least amount of scrap and, potentially, removes the extra cost of welding materials together on-site at the transformer facility.

For example, providing your supplier, Comet Metals, the number of pounds needed per individual unit in advance assists in a variety of ways. It helps avoid any internal extra welding processes, avoid being short on the material when welding is not an option, and also helps you to avoid extra internal scrap costs due to excess material.

These vital pieces of information on transformer coil sizes can help Comet Metals utilize the best materials for your transformer, with the least amount of scrap. It seems simple, but the more information you can provide to us, the better we can help with your requirements.

With hundreds of thousands of pounds of various coil sizes in stock, Comet Metals strives to provide optimal materials for all our customers’ needs so they can achieve the most profitable results.