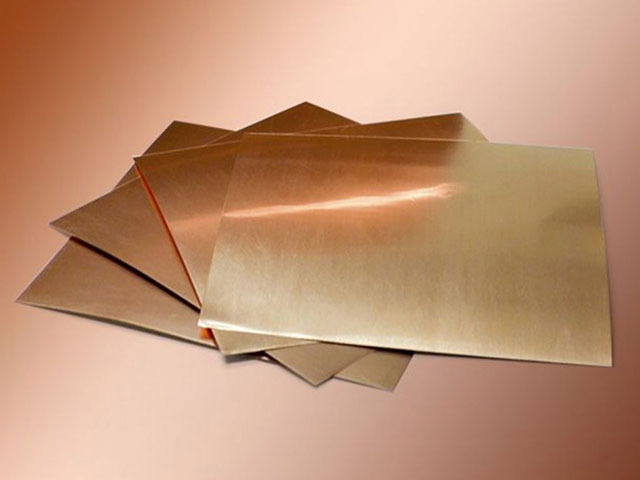

Of all the metals available, copper is the one that has earned the reputation for being the best electrical conductor. That being the case, there are several good reasons for using copper foil instead of aluminum in transformers. Comet Metals takes a closer look at some of the benefits of using our copper foil in your transformer applications.

Benefit #1 of Using Copper Foil in Transformers:

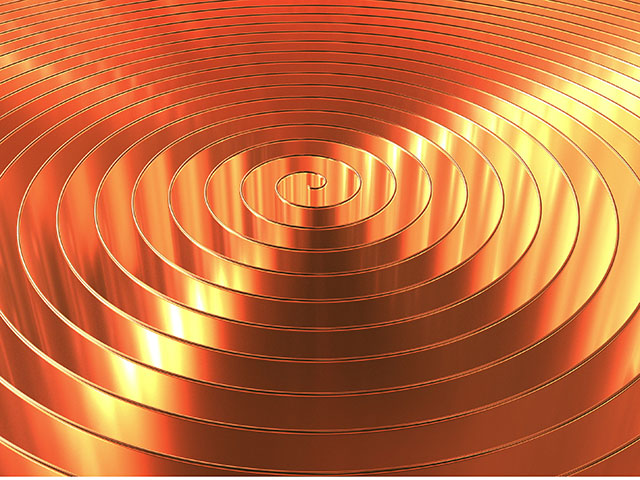

Incomparable electrical conduction – This copper quality can’t be stressed enough. In fact, there is really no competition between copper’s conductivity and aluminum’s. Volume for volume the latter’s conductivity is less than 66 percent that of copper.

Benefit #2 of Using Copper Foil in Transformers:

Copper foil transformers are smaller than aluminum transformers. Copper may weigh more than aluminum, but it makes up for that heftiness with its remarkable ability to pack a lot of conductivity punch into tiny spaces. If a lightweight material is your sole determining factor, then aluminum might be a better choice. In all other cases, copper is superior.

Benefit #3 of Using Copper Foil in Transformers:

After comparing apples to apples, over time copper is very competitively priced. At first glance, aluminum looks like a more cost-effective transformer solution. And yes, its upfront price tag is lower. But as time goes by and the cost of each material is divided over its useful lifespan, copper actually wins out. Year for year, copper’s durable internal connections even give it an affordability edge. That’s because copper’s anti-corrosive properties allow it to endure for decades, in some cases up to 50 years or more. What’s more, in large transformers, the initial cash layout for copper versus aluminum is virtually the same.

Benefit #4 of Using Copper Foil in Transformers:

Copper boasts a higher reliability rating. Aluminum is prone to failure at a much higher rate than copper is.

Benefit #5 of Using Copper Foil in Transformers:

Less lamination steel is required. This is really an extension of the cost-saving benefit since steel is extremely pricey. Because copper transformers require a smaller core, they don’t necessitate as much laminating as aluminum does.

Benefit #6 of Using Copper Foil in Transformers:

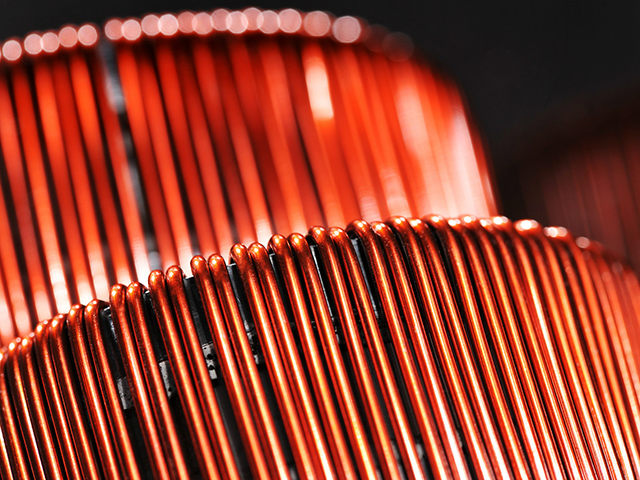

Copper foil is easier to work with when it comes to manufacturing transformers. The diameter of copper conductors is much smaller than aluminum. As a result, the manufacturer can assemble and wrap them with far less complication involved than that entailed in aluminum assembly and wrapping.

Benefit #7 of Using Copper Foil in Transformers:

Copper is a necessary component in conduction. Since there is no way around using some of it, a good case could be made for just sticking with it as the sole conduction material. That is because when the same metal comes in contact with itself (in this case copper), better connectivity all-around results in comparison to contact between dissimilar metals like copper and aluminum.

Benefit #8 of Using Copper Foil in Transformers:

Fewer maintenance issues – The use of two different metals like aluminum and copper sets the stage for connectivity issues. And when contact is disrupted, the entire transformer must be disassembled. Precious human resources are squandered in the process. Worse, the transformer is taken offline, negatively impacting your bottom line.

Comet Metals’ copper foil comes in a wide range of formulations to address the full spectrum of transformer needs. These foils meet the following specs; electrolytic Tough Pitch (110), Oxygen Free (101, 102) and Electro Deposited. Contact us today at 440-201-2235 to discuss your copper needs.