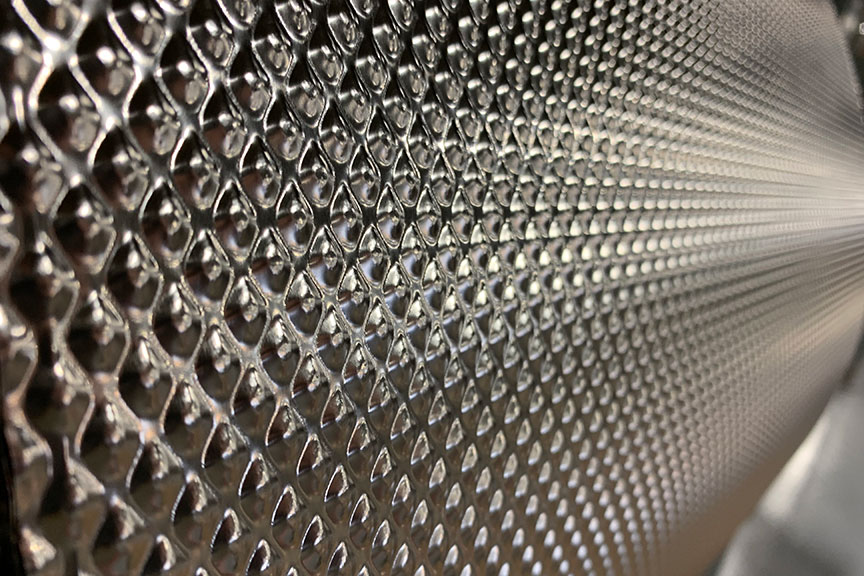

STAINLESS STEEL FOIL ALLOY 316

Stainless Steel Foil Alloy 316 contains 18% chromium, 8% nickel, and 2-3% molybdenum. The addition of molybdenum increases both the corrosion resistance and the high-temperature strength of this alloy. The most outstanding advantage of this addition is the increase corrosion resistance to reducing acids and pitting or pin-hole corrosion. In general, the 316 alloy is known as the major all-around corrosion resistance austenitic stainless steel available. This non-magnetic, non-heat treatable alloy possesses excelling cold forming and drawing properties. It also is rated up to 1500 degrees Fahrenheit.

Standard Specifications: AMS-5524, AMS-5507, ASTM A 167, QQS-766, MILS-5059

For more information about Stainless Steel Alloy 316 or any other Stainless Steel foils we stock please contact us at 1-888-539-5602 or email us.

Comet Metals welcomes any opportunity in Stainless Steel Foil, Stainless Steel Coil or sheet products that you may require. Call us at 888-539-5602 today for a quote and learn for yourself how Comet Metals can assist you in your converter projects. The specifications shown on these pages are not for design purposes.

![]()

| AMS Spec Number: | 5524 |

| ASTM Standards: | A666 |

| Finish: | Standard Finishes |

| Temper: | MOST Tempers |

| Thickness: | 0.001 to 0.032 in |

| Width: | 0.375 to 36 in |

| Carbon (C): | 0.08% |

| Chromium (Cr): | 17% |

| Manganese (Mn): | 2% (Max) |

| Molybdenum (Mo): | 2.5% |

| Nickel (Ni): | 12% |

| Nitrogen (N): | - |

| Other Total: | - |

| Coefficient of Thermal Expansion: * | 8.9 Inches/inch/°F x 106 |

| Density: ** | 0.286 lbs./cu.in. |

| Electrical Conductivity: *** | 444 % IACS |

| Elongation (1/2 Hard): | 6 (Min) |

| Elongation (1/4 Hard): | 10 (Min) |

| Elongation (3/4 Hard): | 3 (Min) |

| Elongation (Annealed): ✦ | 40 (Min) |

| Elongation (Full Hard): | 1 (Min) |

| Modulus Of Elasticity: ⁑ | 28 x 106 psi |

| Rockwell (1/2 Hard): | B95 |

| Rockwell (1/4 Hard): | B95 |

| Rockwell (Annealed): ↠ | B95 |

| Tensile Strength (1/2 Hard) | 150 to 175 x 1000 psi |

| Tensile Strength (1/4 Hard) | 125 to 150 x 1000 psi |

| Tensile Strength (3/4 Hard) | 175 to 200 x 1000 psi |

| Tensile Strength (Annealed): ✧ | 75 to 100 x 1000 psi |

| Tensile Strength (Full Hard): | 185 (Min) x 1000 psi |

| Thermal Conductivity: ♦ | 9.3 BTU per sq.ft.per hr. per °F |

| Yield Strength (1/2 Hard) | 110 (Min) x 1000 psi |

| Yield Strength (1/4 Hard) | 75 (Min) x 1000 psi |

| Yield Strength (3/4 Hard) | 135 (Min) x 1000 psi |

| Yield Strength (Annealed): ↡ | 30 (Min) x 1000 psi |

| Yield Strength (Full Hard): | 140 (Min) x 1000 psi |

| * Inches/inch/°F x 106 from 68°F to 572°F (20°C to 300°C) ** Lbs.per cu.in. at 68°F (Annealed) ( x 27.68 gms./cu.Cm. at 20°C) *** % IACS at 68°F (20°C) as annealed ✦ % in 2 inches ⁑ x 106 PSI, tension ↠ 0.020 gauge and above (30T scale) ✧ x 1000 psi ♦ 9.4 BTU per sq.ft.per hr. per °F ↡ 0.2% offset |