ALUMINUM ALLOY 1235

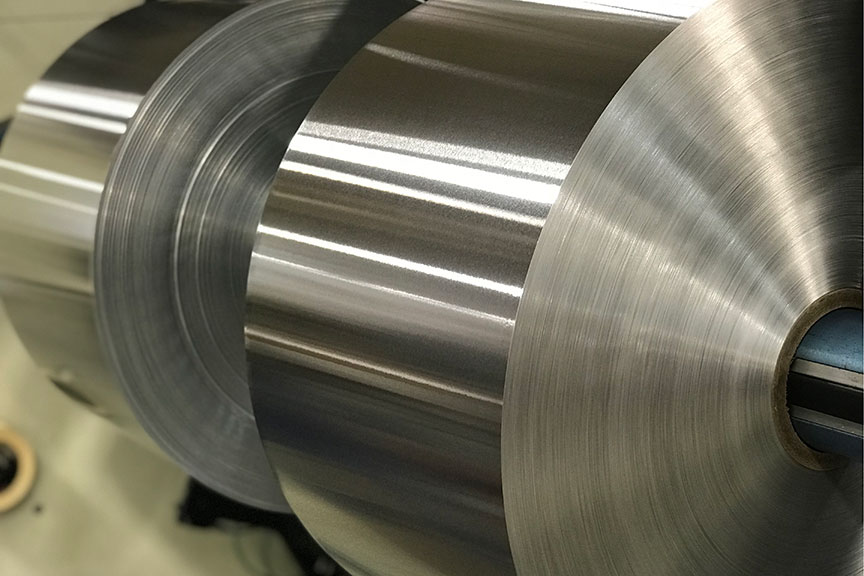

With a minimum content of 99.35%, Aluminum Alloy 1235 has become the most common foil alloy on the market today. It’s fairly high aluminum content makes it an excellent alloy for a variety of industrial and food service markets. In the annealed states, it’s very malleable allowing for easy workability and formability. A very similar alloy to 1145 as it contains almost the exact same chemical composition and the same physical attributes. At times, it can be used as a substitute for the 1145 alloy, which is becoming less common in the market today.

Standard Specifications: QQA-1876, ASTM B209

Comet Metals welcomes any opportunity in Aluminum Foil, Aluminum Coil or sheet products that you may require. Call us at 888-539-5602 today for a quote and learn for yourself how Comet Metals can assist you in your converter projects. The specifications shown on these pages are not for design purposes.

![]()

| ASTM Standards: | B209 |

| Finish: | Standard Finishes |

| QQA Standards: | 1876 |

| Temper: | Standard Tempers |

| Thickness: | 0.0005 to0.064 in |

| Width: | 0.375 to 60 in |

| Aluminum (Al): | 99.35% |

| Chromium (Cr): | - |

| Copper (Cu): | 0.05% |

| Iron (Fe): | - |

| Magnesium (Mg): | 0.05% |

| Manganese (Mn): | 0.05% |

| Other Total: | - |

| Silicon (Si): | 0.65% (Si+Fe) |

| Titanium (Ti): | 0.06% |

| Zinc (Zn): | 0.10% |

| Elongation (Annealed): * | 35 |

| Elongation (H12): | 12 |

| Elongation (H14): | 9 |

| Elongation (H16): | 6 |

| Elongation (H18): | 5 |

| Tensile Strength (Annealed): ** | 13 |

| Tensile Strength (H12): | 16 |

| Tensile Strength (H14): | 18 |

| Tensile Strength (H16): | 21 |

| Tensile Strength (H18): | 24 |

| Yield Strength (Annealed): ** | 5 |

| Yield Strength (H12): | 15 |

| Yield Strength (H14): | 17 |

| Yield Strength (H16): | 20 |

| Yield Strength (H18): | 22 |

| * % in 2 inches ** KSI |