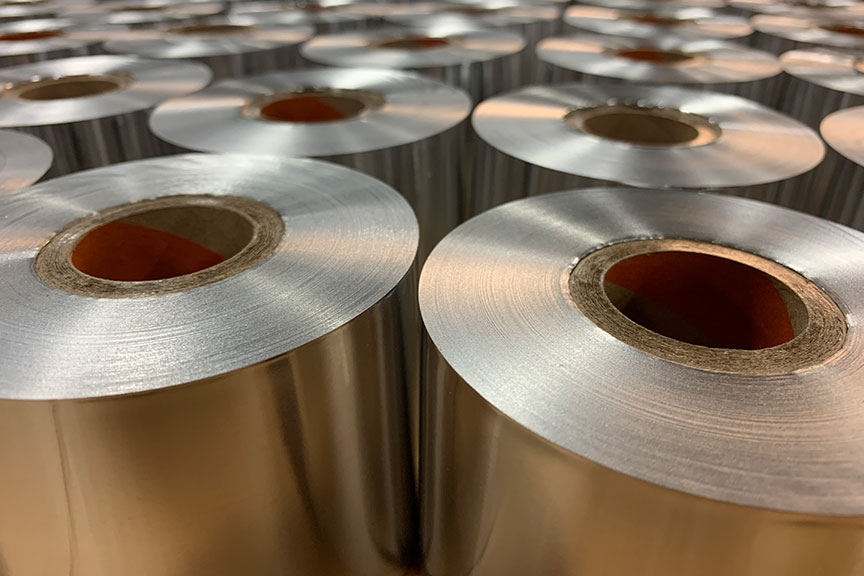

ALUMINUM ALLOY 1100

A commercially pure aluminum, alloy 1100 contains no more than one percent of other chemical elements. It is your standard alloy containing a minimum of 99.0% aluminum. It is both formable and weldable. Typical markets include chemical equipment, reflectors, heat exchangers, architectural applications, and many more. The 1145 and 1235 alloys can be used as substitutes except when comparing burst values when strength is critical.

Comet Metals welcomes any opportunity in Aluminum Foil, Aluminum Coil or sheet products that you may require. Call us at 888-539-5602 today for a quote and learn for yourself how Comet Metals can assist you in your converter projects. The specifications shown on these pages are not for design purposes.

![]()

| Aging: | This material will not age, but can oxidize when left in an extremely damp environment and/or when Exposed to extreme temperatures in both hot and cold environments. |

| Annealing: | Annealing, which may be necessary after cold working. The material is heated to 650°F and then air cooled. |

| Applications: | Commonly used as tapes, fin stock, heat exchanger fins, tags, and names plates, Commercial filters, decorative applications, giftware, and reflectors, and in sheet metal work. |

| ASTM Standards: | B209 |

| Cold Working: | This is a excellent alloy for cold working because of the good malleability in the annealed temper. It can easily be bent, drawn, or spun into a variety of applications. |

| Finish: | Standard Finishes |

| Forging - Hot Working: | Hot working can be conducted when needed. The alloy can be hot forged. |

| Forming - Welding: | Forming either hot or cold is readily accomplished with this alloy. In the annealed condition this alloy can be cold worked extensively without an intermediate anneal. Easily welded by all conventional methods. |

| Hardening: | Hardens during cold working only. |

| Heat Treatment: | This alloy does not respond to heat treatment other than to anneal the material into a soft or O Temper material. |

| Other Physical Properties: | Properties: Electrical conductivity is 53% of copper. |

| Principal Design Features: | This alloy is 99.0% min pure aluminum with excellent ability to be formed and worked. |

| QQA Standards: | 1876 |

| Temper: | This material is available in a variety of tempers. |

| Thickness: | 0.0005 to 0.064 in |

| Width: | 0.375 to 60 in |

| Aluminum (Al): | 99.00% |

| Chromium (Cr): | - |

| Copper (Cu): | 0.05 to 0.20% |

| Iron (Fe): | - |

| Magnesium (Mg): | - |

| Manganese (Mn): | 0.05% |

| Other Total: | 0.15% |

| Silicon (Si): | 0.95% (Si+Fe) |

| Titanium (Ti): | - |

| Zinc (Zn): | 0.10% |

| Elongation (Annealed): * | 35 |

| Elongation (H12): | 12 |

| Elongation (H14): | 9 |

| Elongation (H16): | 6 |

| Elongation (H18): | 5 |

| Other Mechanical Properties: | Shear strength values are: “O” (annealed) temper 9 KSI, H12 temper 10 KSI, H18 temper 13 KSI. |

| Tensile Strength (Annealed): ** | 13 |

| Tensile Strength (H12): | 16 |

| Tensile Strength (H14): | 18 |

| Tensile Strength (H16): | 21 |

| Tensile Strength (H18): | 24 |

| Yield Strength (Annealed): ** | 5 |

| Yield Strength (H12) | 15 |

| Yield Strength (H14): | 17 |

| Yield Strength (H16): | 20 |

| Yield Strength (H18): | 22 |

| * % in 2 inches ** KSI |